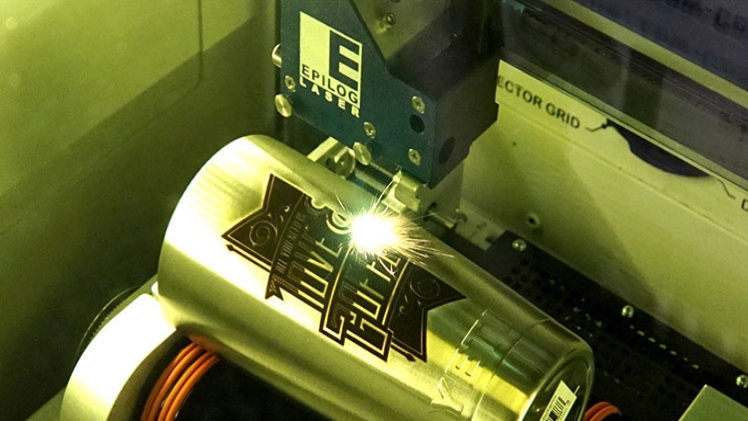

Laser engraving metals with barcodes, serial numbers, and emblems are very famous marking packages on each CO2 and fiber laser structures.

Thanks to their lengthy operational life, loss of required protection and comparatively low cost, fiber lasers are a really perfect preference for commercial marking packages. These styles of lasers produce a excessive-evaluation, everlasting mark that doesn’t have an effect on component integrity.

When marking naked steel in a CO2 laser, a unique spray (or paste) is used to deal with the steel previous to engraving. The warmness from the CO2 laser bonds the marking agent to the naked steel, ensuing in an everlasting mark. Fast and affordable, CO2 lasers also can mark different styles of substances – inclusive of woods, acrylics, herbal stone, and more.

Laser Differences

More time is needed for marking metals with a CO2 laser, for instance, due to the want for coating or pre-treating with a steel marking agent. The laser needs to additionally be run at a low-pace, excessive-strength configuration to permit the marking agent to correctly bond with the steel. Users now and again discover that they may be capable of wipe off the mark after lasering – an illustration that the piece need to be run once more at a decrease pace and better strength setting.

The gain of steel marking with a CO2 laser is that the mark is surely produced on pinnacle of the steel, without disposing of fabric, so there’s no effect at the steel’s tolerance or strength. It need to additionally be cited that lined metals, inclusive of anodized aluminum or painted brass, do now no longer require pre-treatment.

Types of Marks

In order to high-quality fit the form of fabric being marked, a fiber Laser marking on metals machine gives a variety of options. The primary manner of engraving entails the laser beam vaporizing fabric from the floor of an object. The mark is mostly a cone-fashioned indentation, because of the form of the beam. Multiple passes via the machine can create deep engraving, which removes the opportunity of the mark being worn in harsh-surroundings conditions.

Ablation is much like engraving, and frequently related to disposing of a pinnacle coating to reveal the fabric underneath. Ablation may be finished on anodized, plated and powder-lined metals.

Considerations whilst Marking Metal with a Laser

How laser types, marking goals, and fabric preference have an effect on steel marking.

When marking naked steel in a CO2 laser, a unique spray (or paste) is used to deal with the steel previous to engraving. The warmness from the CO2 laser bonds the marking agent to the naked steel, ensuing in a everlasting mark. Fast and affordable, CO2 lasers also can mark different styles of substances – inclusive of woods, acrylics, herbal stone, and more.

Both fiber and CO2 laser structures synthetic with the aid of using Epilog may be operated from nearly any Windows-primarily based totally software program and are fantastically clean to use.

Material Considerations

By making changes to the laser’s pace, strength, frequency and focus, chrome steel may be marked in diverse ways – inclusive of annealing, etching and polishing. With anodized aluminum, fiber laser marking can frequently obtain a great deal better brightness than a CO2 laser. Engraving naked aluminum, however, outcomes in much less evaluation – the fiber laser will create sun sunglasses of grey, now no longer black. Still, deep engraving blended with oxidizers or color fills may be used to provide a black etch on aluminum.

Similar issues need to be made for marking titanium – the laser has a tendency to create sun sunglasses from mild grey to very darkish grey. Depending at the alloy, however, marks of diverse colors may be completed via adjusting frequency.

Best of Both Worlds

Dual-supply structures can permit organizations with price range or area barriers to growth their versatility and capabilities. It needs to be cited, however, that there’s a drawback: whilst one laser machine is in use, the alternative is unusable.