How a bearing is cared for and maintained significantly influences its performance. If such bearings are not appropriately handled, the equipment would not be able to work at its finest, and it may cause harm if left uncontrolled for too long.

Proper maintenance and handling results in extended bearing life, less downtime, and increased production, contributing to cost savings.

With Bearing Service Centre Melbourne, here are the eight tips for ensuring your bearing is always handled appropriately and improving performance.

Observe precautions when handling bearings.

Bearings are precise parts. As a result, they must be handled and maintained correctly to prevent pollutants from entering. Bearings should be kept horizontally in a clean, dry environment with their original package.

Avoid exposing bearings to airborne pollutants since even a dirt particle in a racetrack can cause abrupt bearing failure. Hammering, pounding, or applying direct force to a bearing is not permitted.

It might result in tapered roller damage and misalignment. Bearings should not be placed if they have been dropped or mistreated, as minor cracks and scratches can cause poor performance and sudden and unexpected bearing failure.

Install the bearing appropriately.

Different bearings need different mounting methods, and the fit will also influence the installation.

When employing a cylindrical bore bearing, it is commonly fitted using the press-fit technique, which involves pushing the directions onto the shafts, or the shrink-fit method, which involves using heat in a certain way to expand the bearing’s diameter.

Remember that only a press fit should be used to exert force. If you apply pressure to the ring without a press-fit, the raceways will be destroyed, and the bearing will not function.

Avoid direct warmth and overheating.

The object’s heat treatment determines the maximum permissible temperature of bearings. The temperature that exceeds the heat limit can ultimately damage or melt the bearing steel, limiting load carrying capability and eventually leading to failure.

Never use an open flame to heat a bearing. Bearing Service Centre Melbourne recommends heating bearings using induction heaters.

Use the necessary tools to maintain the bearings.

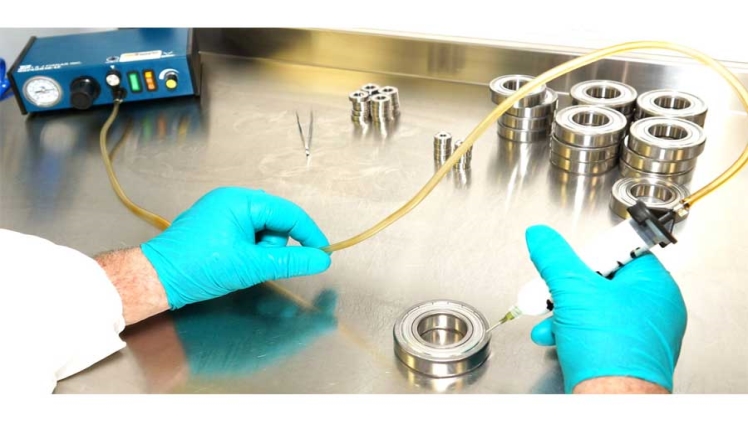

When handling bearings or installing and dismounting, always use the proper gear, bearing pullers, bearing fitting tool kits, oil injector kits, and induction warmers are some of the specialist instruments available for installing and dismounting.

These tools enable a smooth mounting and dismounting operation while reducing the danger of bearing damage.

When working with bearings, avoid using general-purpose tools. These are not designed for bearings and may cause needless destruction and maintenance expenses.

Prevent degenerated bearings.

Rust and corrosion may develop if the bearing is exposed to water over time. It might result in premature bearing fatigue, affecting equipment productivity and effectiveness and increasing operational expenses.

Wear gloves while handling bearings because moisture on your hands, water, or other impurities can cause corrosion. Water-resistant grease can also be used as a lubricant, acting like a protective layer in moist situations.

Consider employing bearings made of alternative materials in very corrosive situations, such as ceramic bearings. You can seek assistance from Bearing Service Centre Melbourne.

Proper lubrication is critical.

Proper lubrication is critical if you want your bearings to last long. Lubricants can be oil or grease, and several criteria, including weather conditions, determine the appropriate lubricant.

Follow the recommendations of your bearing manufacturer, Bearing Service Centre Melbourne, for the best grade and kind of lubrication. Using the proper lubricant might cause machine failure or void the warranty. Check oil levels regularly and replace lubricants at least once a year.

Look out for warning indications.

Excessive noise, a rise in temperature, or odd vibration are indicators of something wrong in the bearing. Monitor them closely, and if required, remove the bearing before causing more harm to your machine parts.

Vibration analysis might assist you in tracking and detecting bearing hazard indications sooner than you would be capable of on yourself alone.

It is used in conjunction with monitoring systems, which may involve thermography and oil analysis, to monitor and compare the present status of the bearing with previous data. It will allow you to estimate the bearing’s remaining life accurately.

Proper bearing maintenance is critical to ensuring that your equipment and machines operate at peak efficiency. Bearing Service Centre Melbourne is a reliable source for bearings.

Seek assistance or call in the experts

Lastly, if you’re in doubt, contact Bearing Service Centre Melbourne. A bearing specialist can guide you on the optimum maintenance strategy for your application and assist you in diagnosing any bearing difficulties.

It may be as simple as sending your troublesome bearings to Bearing Service Centre Melbourne, which will examine and relubricate them.